Cellulose acetate is made from natural materials and returns to nature after use. Daicel has manufactured it as one of major product since 1930s. Through our people- and earth-friendly cellulose acetate, we are contributing to the emergence of a sustainable society.

Natural Ingredients

To ensure efficient use of natural resources, we use trees and cotton plants that have been systematically cultivated specifically as raw materials. Cellulose acetate is made with cellulose obtained from wood produced in sustainably managed forests as well as cotton linters (the hairy fibers that cling to cotton seeds after harvesting).

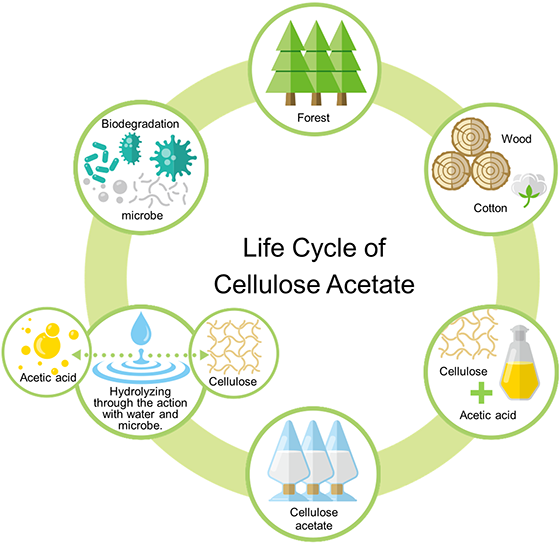

The Life Cycle of Cellulose Acetate

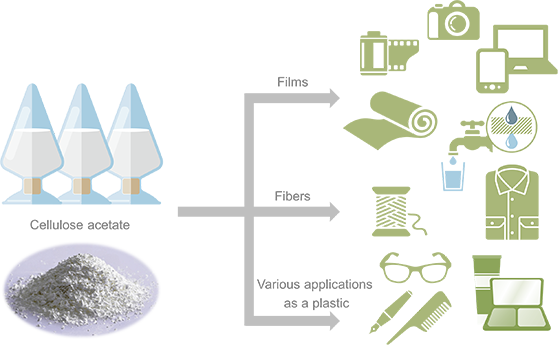

Cellulose acetate is made from cellulose obtained from non-edible plants and acetic acid, the main constituent of vinegar. It can be processed in various ways like common synthetic plastics, and is used in wide range as a raw material for fibers, films for protecting LCDs, cosmetics and others.

Unlike most typical synthetic plastics, those made with cellulose acetate break down after use into cellulose and acetic acid by the action of water in the natural environment. These materials eventually return to the environment with no adverse impact. What’s more, water and microorganisms eventually decompose the cellulose into carbon dioxide and water that can be used to nourish plants once again.

Decomposition in the Natural Environment

In recent years, the challenge of dealing with plastic waste has become an urgent global issue. Much attention has been placed on problems resulting from the large quantities of plastics that have been allowed to flow into the seas.

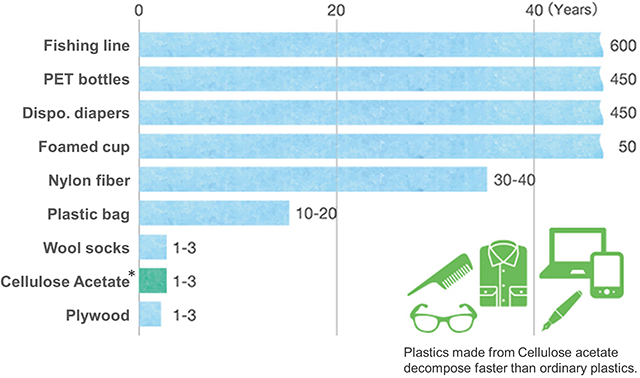

Compared with common synthetic plastics, however, cellulose acetate decomposes quite rapidly in both seawater and soil (Figs. 1 and 2).

Figure 1. Decomposition Time in the Ocean Environment (from our own data and the following sources)

- •U.S. National Park Service; Mote Marine Lab, Sarasota, FL and “Garbage In, Garbage Out,” Audubon magazine, Sept/Oct 1998

- •"The Problem of Marine Plastics” (WWF Japan)

https://www.wwf.or.jp/activities/basicinfo/3776.html (Japanese site) - •New Aspects of Cellulose Acetate Biodegradation, Dirk HÖLTER, Philippe LAPERSONNE, 2017_ST13

- *Cellulose diacetate used for plastics and cigarette filters

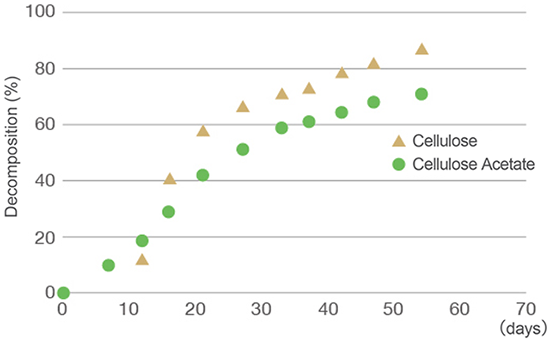

Figure 2. Marine Biodegradability (compared to polylactic acid, a typical biodegradable plastic)

Compiled from Daicel’s data on biodegradability tests outlined in the literature1 and by external organizations2

(1) New Aspects of Cellulose Acetate Biodegradation, Dirk HÖLTER,Philippe LAPERSONNE, 2017_ST13

(2) Chemicals Evaluation and Research Institute, Japan

We are developing a highly biodegradable cellulose acetate "CAFBLO™" which has approximately two times biodegradation rate of conventional products in seawater.

Our Initiatives

More than 300 million tonnes of plastics are produced globally every year. Of this total, a mere 2.1 million tonnes of plastic were made from biomass (biological resources) in 2018 (Source: “Bioplastics Market Data 2018”).

We are currently developing new types of cellulose acetate with the goal of incorporating them into everyday products. Through our focus on cellulose acetate, we are continuing to contribute to the emergence of a sustainable society.