Sustainability / Environmental ReportResponse to Climate Change

Basic Approach

The Daicel Group has set out its Medium- and Long-term Reduction Target for reducing GHG emissions under the Daicel Group’s Basic Policies for Responsible Carewith the goal of realizing a carbon neutral society. We will reduce GHG emissions throughout the Group by significantly reducing energy consumption through a fundamental review of our production processes and the introduction of new technologies, and by switching fuels, optimizing energy consumption, introducing renewable energy sources, and utilizing biomass and recycled materials.

Medium- and Long-term Reduction Target for GHG Emissions

Medium- and Long-term Reduction Target for GHG Emissions

- FY2051/3: Achieve carbon neutrality*1

- FY2031/3: 50% reduction in GHG emissions (compared to FY2019/3)*2

- *1Applicable to the Daicel Group’s Scope 1, 2 and 3 emissions

- *2Applicable to the Daicel Group’s Scope 1 and 2 emissions

To achieve carbon neutrality by FY2051/3, we designated a medium-term target of reducing GHG emissions by 50%, compared to FY2019/3 levels, by FY2031/3. This target references the level of reductions required to limit the global rise in temperature to the SBT* of 1.5°C above pre-industrial levels as laid out by the Paris Agreement. To meet our Medium- and Long-term Target, we will further develop our energy-saving initiatives and promote the reduction of GHG emissions and to adhere to the framework of Science Based Targets (SBTs).

In May 2023, we joined the METI-led GX (green transformation) League with the aim of realizing a carbon-neutral society through the collaboration between industry, government, and academia.

*Science-Based Targets: Medium- to long-term reduction targets for companies, consistent with the Paris Agreement to “hold the average global temperature to well below 2°C above pre-industrial levels” and make efforts to “limit the temperature increase to 1.5°C above pre-industrial levels.”

Promotion System for GHG Emission Reductions

In July 2023, we changed the name of the Energy Strategy Committee to the Carbon Neutral Strategy Committee in order to further accelerate carbon neutral initiatives.

The Energy Strategy Committee was developed out of the Energy Conservation Promotion Committee, which operated until July 2020 under the direct oversight of the President and CEO. The Energy Strategy Committee is chaired by the officer in charge of the Production Management Headquarters (General Manager of the Production Management Headquarters) and members include representatives from production, energy supply, and other corporate divisions in Japan. The committee will take the lead in promoting and managing energy conservation for the Group as a whole. At the same time, to achieve our GHG emission reduction targets, the entire Group will promote the building of a circular process that reduces emissions in current production processes and energy use, as well as through the use of innovate technologies.

With the aim of achieving our Medium- and Long-term Reduction Target and in order to propose and carry out appropriate investment plans, we launched an internal carbon pricing system in April 2025.

Structure of the Carbon Neutral Strategy Committee

Initiatives for Reducing GHG Emissions

Reduction of GHG Emissions

In FY2025/3, GHG emissions for the Daicel Group increased by 4 ten thousand t-CO2e from the previous fiscal year to 231 ten thousand t-CO2e (up 1.9% year-on-year). This is broken down into 173 ten thousand t-CO2e (up 1.4% year-on-year) in GHG emissions at Daicel’s business sites and domestic Group companies, and 58 ten thousand t-CO2e (up 3.3% year-on-year) in GHG emissions at overseas Group companies.

Energy consumption has a major impact on GHG emissions. In FY2025/3, energy consumption for the Daicel Group increased by 0.02% year-on-year, to 839 thousand kL in crude-oil equivalent.

In FY2025/3, energy-derived CO2 emissions for Daicel’s business sites (including the head offices) decreased to 134 ten thousand t-CO2e (down 1.5% year-on-year).

In order to ensure the reliability of the content of the report, a third party* regularly vouches for our calculations concerning GHG emissions.

In addition, in FY2024/3, we established an issue-specific subcommittee, the Life Cycle Assessment (LCA) Subcommittee, within the Sustainable Management Committee. Utilizing LCA methodology, we calculate the carbon footprint (CFP) of each product and work toward its reduction.

Quantitatively visualizing environmental impact can help us reduce the environmental impact of existing products and develop new environmentally friendly materials and other products.

*Emissions of Scope 1, 2 and 3 at Daicel’s business sites are calculated and verified by a third party.

ESG DataRefer to page 1 "Response to Climate Change."

Energy Consumption

- *1Only fossil fuels were included until FY2023/3. However, due to the amendment of the energy conservation related laws in Japan, non-fossil fuels are included from FY2024/3 onwards (converted to crude-oil equivalent).

- *2Energy intensity is measured by the quantity of energy required per unit of output or activity. In an index of energy intensity, the energy intensity is the quantity of energy required per unit output, and the energy intensity of a reference year is treated as 100. The power sold externally has been included in this calculation from FY2017/3, in accordance with the revised Electricity Business Act.

GHG Emissions (Scope1, 2)

Reducing GHG Emissions across Daicel’s Supply Chain

We believe that GHG emissions must be reduced by both the Daicel Group and its supply chain, and we have been working to identify and reduce the volume of GHG emissions based on the GHG Protocol, the world’s most widely used standard, since FY2021/3. In addition, domestic emissions of CO2, CH4, N2O, SF6, and NF3 are calculated according to the emissions coefficients established in the Act on Promotion of Global Warming Countermeasures (Global Warming Law), plus N2O emissions from scrap tires.

Additionally, in anticipation of future sustainability information disclosure, such as CSRD and SSBJ, we are working to expand the scope of GHG emissions calculations to all of Scope 3, and broaden the boundaries to encompass the entire Daicel Group.

GHG Emissions by Scope in FY2025/3

Scroll left or right

| Categories | Emissions (ten thousand t-CO2e) |

||

|---|---|---|---|

| Scope 1*1 | Direct GHG emissions | 149 | |

| Scope 2*1 | Electricity indirect GHG emissions | 5 | |

| Sum of Scope 1,2*1 | 153 | ||

| Scope 3 | Other indirect GHG emissions | 146 | |

| Category 1*2 | Purchased goods and services | 110 | |

| Category 2*3 | Capital goods | 20 | |

| Category 3*2 | Fuel- and energy-related activities (not included in Scope 1 or Scope 2) | 12 | |

| Category 4*2 | Upstream transportation and distribution | 1 | |

| Category 5*2 | Waste generated in operations | 1 | |

| Category 6*4 | Business travel | 1 | |

| Category 7*4 | Employee commuting | 0 | |

| Sum of Scopes 1, 2, and 3 | 300 | ||

- *1Daicel's business sites (including the headquarters)

- *2Daicel's business sites

- *3Daicel Group

- *4Daicel's business sites and domestic Group companies

Calculation Methods

Based on the Ministry of the Environment and METI’s Basic Guidelines on Accounting for Greenhouse Gas Emissions Throughout the Supply Chain (Ver. 2.7), we used the guideline’s Emissions Unit Values Database for Accounting of Greenhouse Gas Emissions, etc., by Organizations Throughout the Supply Chain (Ver. 3.5), AIST-IDEA for life cycle analysis, and emission factors in the calculation, reporting, and publication system for the Law Concerning the Promotion of the Measures to Cope with Global Warming, etc.

Initiatives to Reduce the Environmental Impact of Logistics Operations

The Daicel Group is striving to curb energy consumption associated with product transportation through initiatives that include promoting a modal shift*1 and container round use.*2 In FY2025/3, the amount of energy used for logistics was 4.9 thousand kL, a decrease of 7.5% from the previous fiscal year.

- *1Shifting freight transport currently handled by trucks to more environmentally friendly modes such as shipping or rail transport.

- *2Reusing the same container for export that was used for import.

Energy Consumption and Energy Consumption Rates in Logistics Operations (Daicel’s business sites and domestic Group companies)

CO2 Emissions/Intensity (Daicel’s business sites)

Reduction in Transport CO2 Emissions from the Modal Shift and Other Measures

In 2007, Daicel Logistics Service switched from road to sea transport between the main ports for imports and exports and Daicel’s plants in order to reduce CO2 emissions generated from logistics. In addition, we have reduced the transportation distance and CO2 emissions by changing the port for exports to ports located near our plants. In FY2025/3, we reduced CO2 emissions to 73% of those for land transportation through modal shifts, including the use of about 7,100 containers* per year for marine transportation.

*Calculated on the basis of 40-foot containers.

Promoting Container Round Use

Reusing imported goods containers for exporting products can reduce CO2 emissions associated with the transport of empty containers. Daicel Logistics Service Co., Ltd. has adopted the round use method for containers for export and import operations to further reduce CO2 emissions. This also saves energy by realizing smooth, efficient transport based on its proprietary system for facilitating the matching process for each shipping company. In addition, we strive to ensure safe and efficient transport by reviewing the standards for container use and implementing simple repairs as needed.

Daicel Logistics Service: Modal Shift and Round Use (Japanese text only)Reducing GHG Emissions from Three Angles

The Daicel Group has responded to climate change through the building of a circular process, which will enable us to run our business in harmony with the global environment, from the three aspects of reductions in GHG emissions: reductions in GHG emissions in current production processes, innovative technology, and the energy supply division.

Reduction in GHG Emissions in Current Production Process

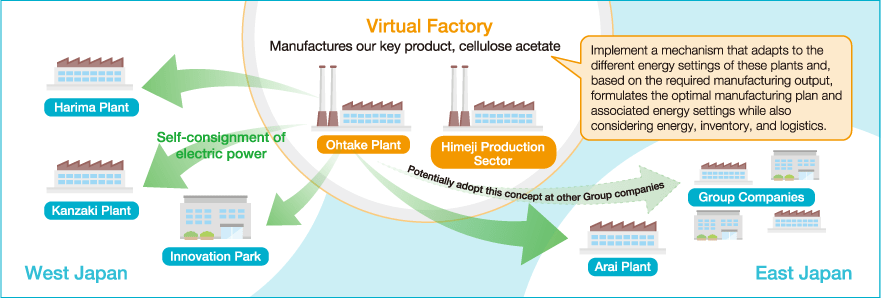

Energy consumption by the Himeji Production Sector and Ohtake Plant accounts for 92% of overall consumption at Daicel’s business sites. We treat these as if they were a single factory in cyberspace (a virtual factory*) and centrally manage information related to their manufacturing processes. Furthermore, optimal operation considering quality, cost, and the environment is achieved through an autonomous production system, which has been advanced by artificial intelligence (AI) developed in joint research with the University of Tokyo based on the Intellectual and Integrated Production System constructed through DAICEL Production Innovation. We have been steadily implementing this technology in our key acetyl chain plants, and in addition to cellulose acetate and acetate tow, we implemented it in our carbon monoxide plant in FY2025/3. We are also sequentially launching initiatives for organic synthesis plants, starting with peracetic acid derivatives, and plan to expand these efforts to major plants across the company during the next Mid-term Management Strategy period, aiming to reduce GHG emissions.

*A factory model virtually created in a computer as if it were the real thing.

DAICEL Production InnovationIntroduction of the Energy Operation Optimization System

In order to manage our energy consumption in accordance with the optimal manufacturing plan, we have introduced the Energy Operation Optimization System, which provides online monitoring and controls for the most favorable operating conditions based on actual operating conditions and simulations. This system is used by the Himeji Production Sector and Ohtake Plant.

Leveraging the Self-Consignment System

As part of optimizing energy supply and demand, the Ohtake Plant started sending excess generated electricity to other worksites in West Japan using the self-consignment system. Furthermore, the plant began sending electricity to the Arai Plant in East Japan in May 2020, to the Fuji Plant of Polyplastics Co., Ltd. in April 2021, and to the Isesaki Plant of Daicel Pack Systems Ltd. in July 2024. We expect to further extend the system to other Group companies toward achieving zero purchased electricity at the Group level.

The Self-Consignment System

Reduction in GHG Emissions by Innovative Technology

The Daicel Group looks well beyond efforts to improve and refine its technologies when putting in place energy-saving measures. It also works to comprehensively review its production processes and develop new technologies to reduce its GHG emissions. The R&D costs for environmental load reduction in FY2025/3 were ¥231 million.

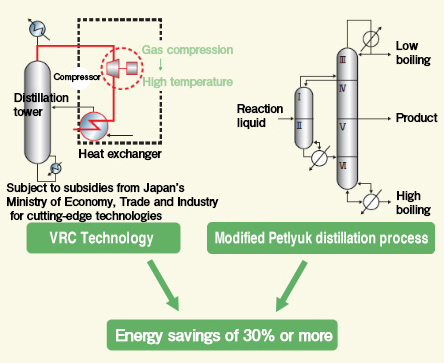

In general, distillation processes tend to account for around 40% of general energy consumption in the chemicals industry. This is also true for Daicel’s operations, so establishing energy-saving technologies in distillation processes is key to achieving significant energy savings. The distillation process utilizes high-temperature thermal energy but also generates large volumes of low-temperature exhaust heat energy that is released unused. With this in mind, it is essential to also develop technology that effectively recovers and reuses low-temperature exhaust heat energy in addition to reducing high-temperature thermal energy use.

The Daicel Group has launched an innovative energy-saving technology project and has been promoting cross-sectional activities throughout every level of the Company. As a result, these efforts have led to the creation of a modified Petlyuk process and vapor recompression (VRC) technology to reduce the energy consumption of distillation towers. Although these basic technologies have been used in industrial processes for a long time, they have not been scaled up for use in large chemical plants, with Daicel being the first in the world to do so.

Moreover, we are engaged in joint research with several universities to establish the technology for melting wood at normal temperature and pressure (which requires less energy) for constructing a new biomass product tree that holds the key to a carbon-neutral future. We are also developing a technology for reducing carbon dioxide into carbon monoxide through a reduction reaction and reusing it. This is to further reduce the amount of CO2 that escapes into the atmosphere even after taking measures to limit CO2 emissions in the manufacturing process.

Enhancing Our Current Technologies

● Modified Petlyuk distillation process

Petlyuk distillation, and its practical application as a dividing-wall column (DWC), is widely recognized as an energy-saving technology. However, implementing a DWC requires the complete replacement of distillation towers since it cannot be retrofitted to existing facilities, resulting in massive amounts of initial expenditure for the installation. By refining Petlyuk technology, Daicel developed a new process technology that allows for its application through improvements to distillation towers. Since 2014, the technology has been applied at the Arai Plant’s acetic anhydride manufacturing facilities. We are also considering introducing this technology to other plants in order to achieve carbon neutrality.

● Vapor Recompression (VRC) Technology

Expectations are mounting that VRC technology will become ubiquitous to recover heat as high-temperature steam by compressing the exhaust heat inherent in low-temperature steam. While this technology has been widely used in aqueous-system simple distillation processes, there have been no examples of its application in organic solvent distillation processes. Aiming to do just this, Daicel has been working with a compressor manufacturer to develop a compressor that would enable the use of VRC technology in organic solvent distillation processes. We have completed verification using a prototype distillation process and we are currently continuing verification through long-term operations. We are also considering horizontal deployment to other facilities.

New Technologies that Adapt to Environmental Change

● Membrane Separation Technology

The evaporation process in distillation consumes massive amounts of energy. Dramatic energy savings, however, are possible if a membrane separation technology is used instead. We are developing membrane separation technology through industry-academia collaboration and are currently conducting demonstration experiments at the Aboshi Plant.

● New Reaction Technology

We developed an innovative process, which leverages a newly developed reaction technology with a new catalyst. It has been installed at the Aboshi Plant’s 1,3-BG facility. We expect that energy consumption will be reduced by approximately 20% compared to that of conventional technologies.

● New Wastewater Treatment Technology (Anaerobic Wastewater Treatment Technology)

Anaerobic wastewater treatment does not require oxygen and therefore requires less energy. In addition, the methane gas generated in the decomposition process can be used for fuel. Following demonstration tests at the Aboshi Plant for full-scale operation, we are reviewing implementation at all plants.

● Appropriate Production Technology with Microfluid Devices

Microfluid devices are devices that have several hundred micrometer channels on their base, so that chemical operations, such as blending, reacting, and distilling can be performed on a micro scale. Parallelizing 10,000 or more microfluid devices allows manufacturing methods that have been established through research to be expanded into mass production, and at the same time, one can adjust the amount produced to save space, conserve energy, and save resources, as well as to produce the amount required as needed. This technology will help make sustainable next-generation production plants a reality. We are proceeding with plans to introduce a demonstration facility for resist polymer manufacturing by the end of FY2026/3.

*1micrometer= 0.001 mm

Reduction in GHG Emissions in the Energy Supply Divisions

Each of the Daicel Group’s plants generates its own steam and electricity for manufacturing, and we will also seek further energy conservation and reductions in GHG emissions by upgrading their facilities, promoting fuel conversion for boilers and procuring green energy such as renewables.

Energy-saving and GHG Reduction Measures at Each Plant

| Aboshi Plant | In September 2012, the plant installed a cogeneration system with gas turbines.In June 2019, it started selling its excess electricity. |

|---|---|

| Ohtake Plant | In August 2007, the plant started selling its excess electricity. In July 2016, it installed an additional boiler. Two dual-fuel boilers are run in parallel using a mix of coal and scrap tires as fuel. |

| Arai Plant | In January 2017, the plant switched from a coal boiler to a cogeneration system with gas turbines. |

Using Fuel Derived from Scrap Tires to Reduce Fossil Fuel Use

In Japan, roughly 100 million scrap tires, or about one million tonnes, are generated each year, placing a considerable load on the environment. On the other hand, about 30% of scrap tires consist of biomass, including natural rubber, making them a superb energy fuel.

Having noticed this characteristic, we carry out thermal recycling at the Ohtake Plant with co-firing of coal and tire chips. The addition of tire chips can reduce the use of fossil fuels and CO2 emissions, so we have been collaborating with manufacturers of power generation equipment, making progress in the improvement of the co-firing rate and developing technologies to generate the necessary level of power safely.

These efforts have yielded some success.

Moreover, we are promoting recycling through the use of particulates and cinders in cement and roadbed improvement agents, which account for about 60% of the total volume of generated waste and the sorting and collection of plastic waste.

In FY2025/3, we sought to improve the quality control of scrap tires and achieved a co-firing rate of 58%, and a fossil fuel usage rate of 44% Going forward, we will continue to reinforce our recycling efforts to bring about a sustainable society.

Changes in the Fossil Fuel (Coal) Usage Rate at Ohtake Plant

Reducing Electricity Purchases with Solar Power Generation

We are also actively utilizing renewable energy sources, such as the introduction of solar power generation systems at Daicel Group production sites. In 2024, the self-generated power from the photovoltaic systems installed at Daicel Safety Systems (Jiangsu) Co., Ltd. and Daicel Safety Systems Europe Sp. z o. o. totaled 3,379 MWh.