CAFBLO® Pellet

Sustainability

01Recyclability

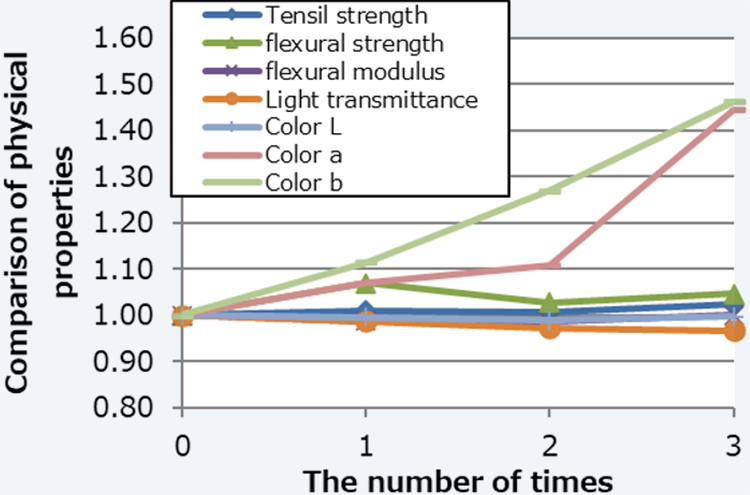

CAFBLO® can be recycled multiple times.

Although CAFBLO® Pellet is a biodegradable resin, there is little physical properties deterioration during repeated molding compared to other biodegradable resins.

CAFBLO®Pellet recycling characteristics

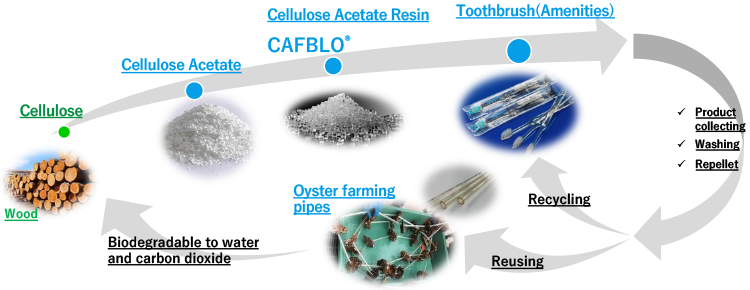

02Marine Disintegration and Biodegradation

CAFBLO® is highly biodegradable in seawater.

It is made from Cellulose acetate, acetic acid and biodegradable plasticizer mainly. These raw materials are biodegraded by microorganisms eventually converted into water and carbon dioxide.

*Point of caution

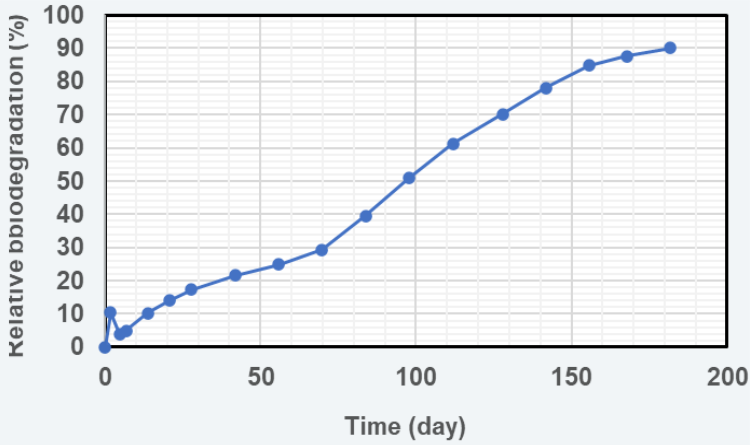

CAFBLO® is marine biodegradable, but please note that the biodegradation speed varies greatly depending on the form (composition, size, thickness, etc.) and natural environment (microbes, temperature, sea water, etc.) of CAFBLO® molded products.

CAFBLO® molded products disintegrating in the ocean

- This is an evaluation for some grades of CAFBLO®.

- These are reference values and do not guarantee quality.

- Test location: Himeji, Hyogo Japan

- Test sample: 6mmΦ Straw (CAFBLO®)

Biodegradability test results of CAFBLO® in the ocean

- This is an evaluation for some grades of CAFBLO®.

- These are reference values and do not guarantee quality.

- Measurement laboratory: OWS

- Compliant Standard: ASTM D6691

- Culture temperature: 30℃

- Reference item: Cellulose

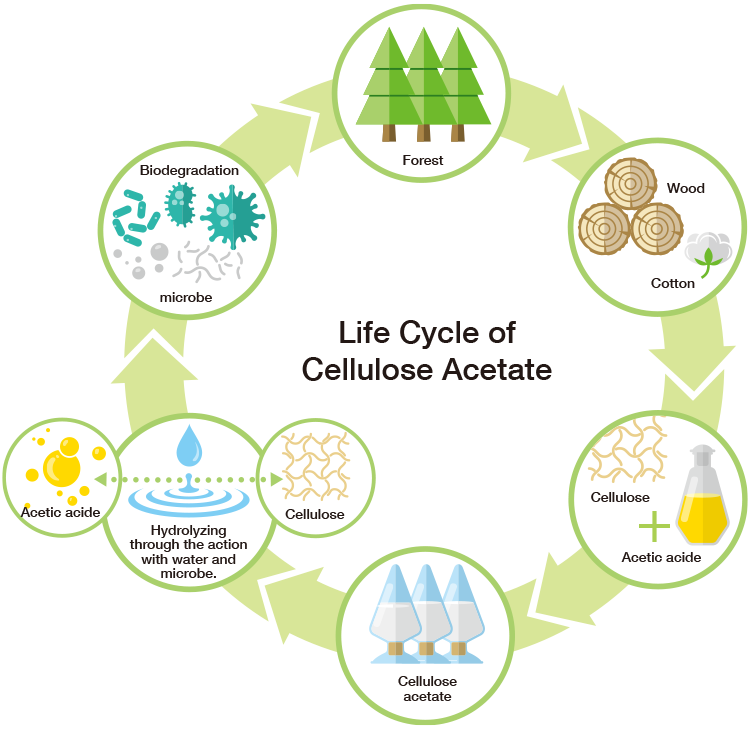

Cellulose acetate is highly biodegradable and has been reported to be biodegradable in seawater.

Cellulose acetate is decomposed into "cellulose" and "acetic acid" by hydrolysis reaction with water and biodegradation by esterase, and then the cellulose main chain is biodegraded by cellulase, finally becoming water and carbon dioxide.

Water and carbon dioxide contribute to the growth of plants, including wood and cotton.

The circulation back to cellulose is established.

03Grade Lineup

CAFBLO® offers balanced mechanical strength, has excellent impact and heat resistance.

Good resistance to petroleum solvents, oil and gasoline.

| Grade | Test Method | Unit | RSS025 | RSF208 | RSF038 |

|---|---|---|---|---|---|

| Features | Standard | High Flow | High Flow | ||

| Density | ISO 1183 | g/cm3 | 1.28 | 1.27 | 1.28 |

| MFR/220℃* 10kg | ISO 1133 | g/10min | 22 | 70 | 12190℃* 10kg |

| Tensile Strength | ISO 527 | Mpa | 53 | 42 | 52 |

| Flexural Strength | ISO 178 | Mpa | 63 | 49 | 47 |

| Flexural Modulus | ISO 178 | Mpa | 2,600 | 2,100 | 1,900 |

| Notched Charpy impact strength | ISO 179/1eA | kJ/m2 | 10 | 11 | 6 |

| Deflection temperature under load/0.45MPa | ISO 75 | ℃ | 92 | NA | 80 |

| Deflection temperature under load/1.80MPa | ISO 75 | ℃ | 66 | 56 | 63 |

- Test methods such as ISO standards are fully or almost compliant with the standards.

- The above property values were measured under dry conditions.

- Values are typical, not quality assured

- Home

- CAFBLO® Pellet

- CAFBLO® Pellet Sustainability