SustainabilityMateriality

The Daicel Group identified its materiality in FY2021/3 as key sustainability issues toward achieving the Accelerate 2025 Mid-Term Management Strategy. We will carry out the CAPD cycle* according to this materiality and contribute to realizing a sustainable society in the Daicel way.

* Instead of a Plan, Do, Check, and Act (PDCA) cycle, the most widely known approach to continuous improvement, Daicel Group has adopted a CAPD improvement cycle to avoid the risk of overlooking crucial facts and realities that often lie hidden in the initial planning stage.

Background and Approach to Identifying Our Materiality

The Daicel Group’s materiality consists of two main categories.

For "Materiality aimed at achieving growth of the Daicel Group and value co-creation," our aim is to leverage the strengths of the Group to address the SDGs and other social issues and actively create value in line with the "Product, Process, and People" concept in our Sustainable Management Policy.

For "Materiality related to the foundations of the Daicel Group’s continuity and governance," we focused on the key foundations of Safety, Quality, and Compliance, which are essential for value creation, across each of the ESG domains: Environment, Society, and Governance.

Process of Identifying Materiality

STEP1Extract social issues

We referenced international guidelines, SDGs, the principles of the United Nations Global Compact and guidelines published by industry organizations to extract social issues that Daicel Group should address.

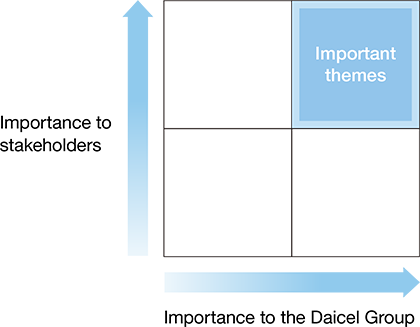

STEP2Prioritize

We assessed items extracted in Step 1 by considering the following aspects to identify key themes with high priority by plotting them on the materiality map according to “Importance to stakeholders” and “Importance to the Daicel Group.” We then sorted them into the two categories of “Growth of the Daicel Group and value co-creation” and “Foundations of the Daicel Group’s continuity and governance.”

- Consistency with the Long-Term Vision and Mid-Term Management Strategy

- Consistency with related policies such as the Sustainable Management Policy, the Daicel Group Code of Conduct, and the Ethical Standards of Daicel Group

- Consolidation of opinions from relevant departments

Materiality Map

STEP3Confirm validity

The Corporate Sustainability Division and other relevant divisions discussed the validity of important themes identified through Steps 1 and 2. The results were reported and approved at the Management Meetings and subsequently endorsed by the Board of Directors.

STEP4Formulate materiality and KPIs

By going through Steps 1 to 3, we identified 15 material issues. We designate a key performance indicator (KPI) and target for each. We will review our materiality, KPIs and targets in response to future changes in society and our business.

Monitoring Materiality

The progress toward identified materiality is regularly monitored alongside defined KPIs and targets. Regular evaluations are conducted at the Sustainable Management Committee and the Board of Directors provides oversight.

Materiality and KPIs

List of Materiality KPIs and Results [PDF:331KB]

Scroll horizontally

Materiality aimed at achieving growth of the Daicel Group and value co-creation

| Classification | Materiality | Content | KPIs | Target | FY2023/3 Results |

FY2024/3 Results |

FY2025/3 Results |

|---|---|---|---|---|---|---|---|

| Sustainable Product | Contribute to beauty and health |

|

Number of our chiral columns used in pharmaceutical analysis methods*1 | FY2026/3: 95 cases (cumulative) |

88 cases | 113 cases (cumulative) |

124 cases |

|

Total number of people provided with functional food ingredients per year | FY2026/3: 2.23 million (twice the FY2021/3 figure) |

1.24 million people | 1.69 million people | 1.62 million people | ||

| Contribute to the smart society |

|

New product rate of safe, high-boiling point solvents essential for advanced semiconductor manufacturing processes*2 | FY2026/3: 23.9% | 3.2% | 7.7% | 8.4% | |

| Provide safety and security for society |

|

Average number of our safety devices installed per vehicle*3 | FY2026/3: 3 units/vehicle |

2 units/vehicle | 2.2 units/vehicle | 2.2 units/vehicle | |

| Diversified small mobility*4 devices and new safety devices to prevent home accidents*5 put on the market | FY2026/3: New safety device proposals, with a total of 2 cases by FY2031/3 | New business proposals: 2 under review | New business proposals: 2 cases | New business development initiatives: 2 cases | |||

| Provide environment-friendly materials and technology |

|

Rate of recyclable raw materials*6 used in products | FY2031/3: 30% or more | 15.9% | 15.8% | 16.5% | |

| Production volume of environment-friendly (highly biodegradable, etc.) cellulose acetate | FY2026/3: 10,000-20,000 tonnes/year | 7,993 tonnes/year | 7,625 tonnes/year | 8,282 tonnes/year | |||

| Sustainable Process | Contribute to the development of a circular society (Only in Japanese) |

|

Number of external proposals for resource recycling systems using natural materials | FY2026/3: 3 cases | Under research and development | 1 case | 1 case |

| Respond to climate change |

|

GHG emission reduction rate of our Group*7 | Scope 1 and 2 FY2031/3: 50% reduction (compared to FY2019/3) | 1% increase | 3.5% reduction | 0.5% reduction | |

| Sustainable People | Promote DE&I |

|

Ratio of women in management positions*8 | FY2026/3: 10% or more | 4.9% | 5.6% | 6.3% |

| Ratio of persons with disabilities that have been with the company more than three years*8 (1 - persons with disabilities that left the company in three years after joining / total number of employed persons with disabilities) × 100 | Sustain 95% or more | 96.0% | 97.4% | 100% | |||

| Support personal growth |

|

Status of initiatives for personnel development, review of human resource system, introduction and review of career seminars or management training for department managers*8 | Disclose results |

|

|||

Scroll horizontally

Materiality related to the foundations of the Daicel Group’s continuity and governance

| Classification | Materiality | Content | KPIs | Target | FY2023/3 Results |

FY2024/3 Results |

FY2025/3 Results |

|---|---|---|---|---|---|---|---|

| Environment | Reduce environmental impact |

|

Percentage of industrial waste recycled by our business sites and domestic Group companies | FY2026/3: 99% or more | 98.4% | 98.0% | 98.6% |

| Social | Ensure process safetyand disaster prevention, occupational health and safety |

|

Number of serious occupational accidents*8 | Continue 0 (zero) cases | 0 cases | 1 case | 0 cases |

| Number of serious process safety incidents*8 | Continue 0 (zero) cases | 0 cases | 0 cases | 0 cases | |||

|

Percentage of safety training held based on past incidents (occupational accidents and process safety incidents)*8 | Continue to 100% | 100% | 100% | 100% | ||

| Ensure chemical safetyandenhance product quality |

|

RC-related regulation audit rate*8 | ●Continue to 100% | 41% | 100% | 100% | |

| Number of violations of chemical regulations | Continue 0 (zero) cases | (Initiative from FY2024/3) | 0 cases | 0 cases | |||

| Number of problems caused by product safety | Continue 0 (zero) cases | (Initiative from FY2024/3) | 0 cases | 0 cases | |||

| Rate of initial response to customer complaints within 24 hours*9 | FY2026/3: 100% | 88.0% | 89.0% | 87.4% | |||

| Rate of completion of customer briefings within 25 days | FY2029/3: 100% | (Initiative from FY2025/3) | 70% | ||||

| Respect human rights |

|

Rate of progress in annual plans for human rights due diligence targeting the Daicel Group | FY2026/3: 100% | 88.7% (FY2020/3–FY2025/3) (19 out of 19 domestic Group companies, 28 out of 34 overseas Group companies)*10 |

|||

| Rate of progress in annual plans for human rights due diligence targeting suppliers | 100% continuation | (Drafting and implementation of plans for human rights due diligence targeting suppliers) | (Conducted human rights due diligence for domestic and overseas suppliers, followed up with suppliers on identified issues and improved 50 cases) | 100% | |||

| Foster a corporate culture that meets employee needs |

|

Rate of continuous paid leave taken*8 (a five-day consecutive leave once per year) | FY2026/3: 100% | 56.3% | 72.3% | 69.2% | |

|

Percentage of male employees who have taken parental leave*8 | FY2026/3: 100% | 97.9% | 89.3% | 94.1% | ||

|

Status of efforts to promote employee health*8 | Disclose results |

|

||||

| Promote sustainable procurement |

|

Sustainable procurement rate (new item set in FY2025/3) Implement FY2025/3 version of SAQ and achieve 100% rate of suppliers (2) that meet standard (1) of our Group.

*The following old KPI was achieved in FY2024/3 (past targets/performance are shown in parentheses) |

FY2026/3: 100% (FY2024/3: 100%) |

(79%) | (100%) | 62% | |

| Governance | Strengthen foundation for Group governanceand compliance |

|

Status of efforts to strengthen the supervisory function by the Board of Directors Evaluation target of the Board of Directors by Outside Directors and Outside Audit & Supervisory Board Members: (out of 5 points) |

Average of 4.0 points or above | (Initiative from FY2024/3) | 4.4 points | 4.3 points |

| Rate at which legal checks are made and response measures taken for material matters requiring executive decision | Continue to 100% | 100% | 100% | 100% | |||

|

Number of issues reported to the Help Line | Disclose results | 76 cases | 102 cases | 126 cases | ||

| Percentage of executives and employees who know how to use the Help Line System and can contact the Help Line when they discover compliance violations*11 ( = percentage of employees who have taken Help Line reporting training) | FY2026/3: 100% | 10% | 18% (1,074 personnel) |

97% (5,988 personnel) |

|||

- *1 Targets: Pharmacopoeias in Japan, the U.S. and Europe

- *2Highly safe high boiling point solvents: Solvents for electronic materials with high solubility and low toxicity such as MMPGAC

- *3Targets: Products for Japanese automakers

- *4Bicycles, mobility scooters, electric kick scooters, etc.

- *5Drowning while bathing indoors, infant suffocation, falls, etc.

- *6Recyclable raw materials: biomass raw material, use of atmospheric CO2, reuse of waste, and recycling

Targets: Main resin materials of Daicel, Polyplastics and Daicel Miraizu. - *7Realization of carbon neutrality in FY2051/3 (Scopes 1, 2, 3)

- *8Scope: Daicel Corporation

- *9Scope: Domestic manufacturing sites of Daicel Corporation

- *10The base number of group companies represents the companies that are candidates for human rights due diligence as of April 2024

- *11Daicel and domestic Group companies