Optical Lenses

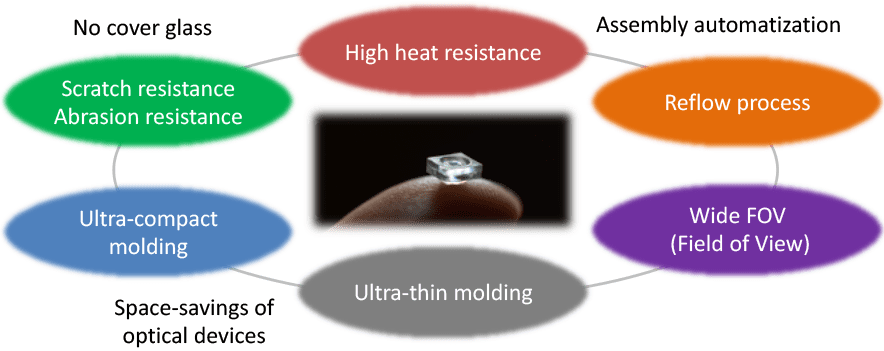

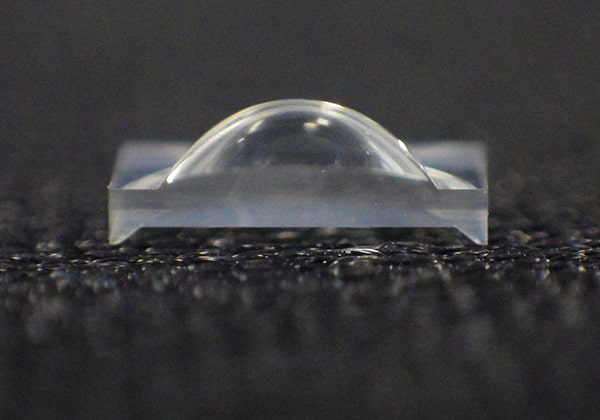

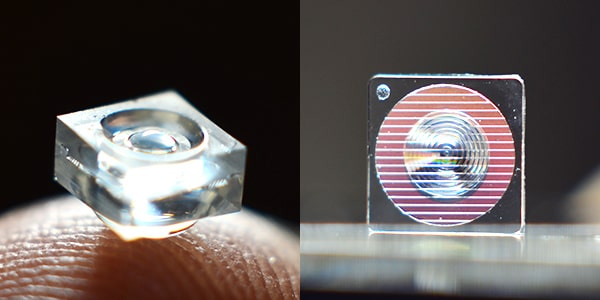

Daicel's Wafer Level Optics (WLO) is made of monolithic plastics, which realize smaller and thinner optical lenses than glass and glass hybrid ones. This opens the door to more complex and unfettered optical design1). Moreover, being far more heat-resistant than general plastic lenses at 260℃ to 150℃ by comparison, our lenses are applicable to automated assembly processes2), which helps customers to improve their productivity. Our WLO is widely adopted for sensing cameras.

- ex. FOV, EFL

- Reflow soldering process at 260℃

Features

the demand of plastic lens is increasing thanks to their better manufacturability than glass, which gives engineers wider design leeway. Yet, lenses made from thermoplastic carry the disadvantage of being weak against heat. However, we manufacture lenses from thermosetting or photo-curable plastics that have long-term heat resistance, so they retain their transparency and shape even after passing through reflow processes of about 260℃, which makes them applicable to automated assembly processing. Moreover, because glass substrates are not needed to manufacture WLO, engineers have broader latitudes of freedom to design lenses of wide field of view or shorter focal length for super-thin, compact devices that require less space.

Molding Technology

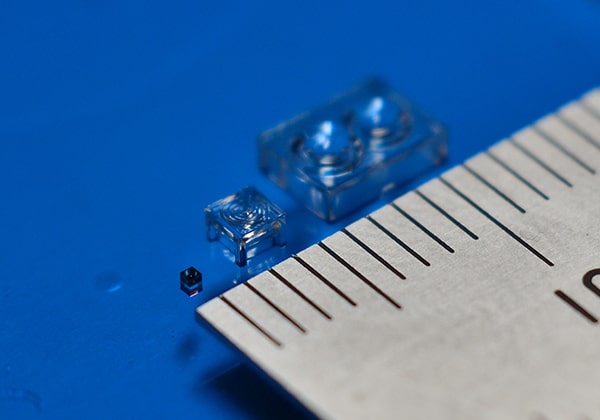

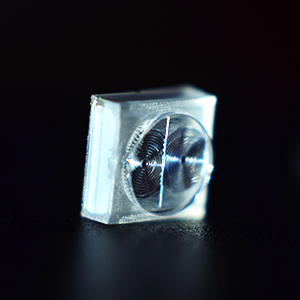

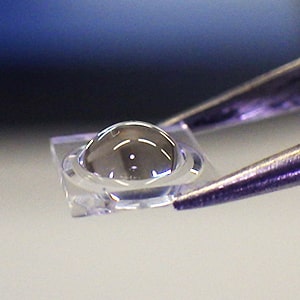

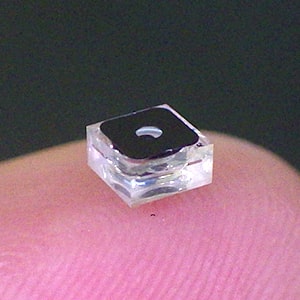

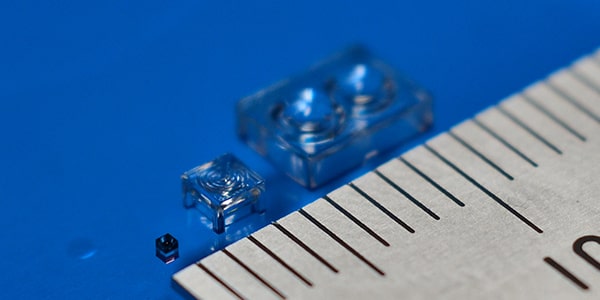

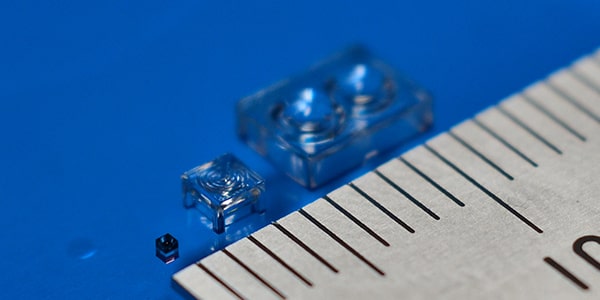

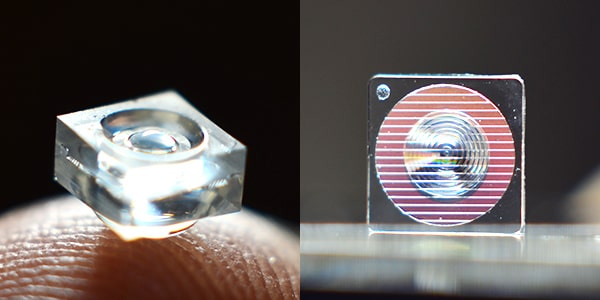

Ultra-compact

molding

We can mass-produce ultra-small stacked lens units measuring 1.0 mm square by taking advantage of the wafer-level lens process.

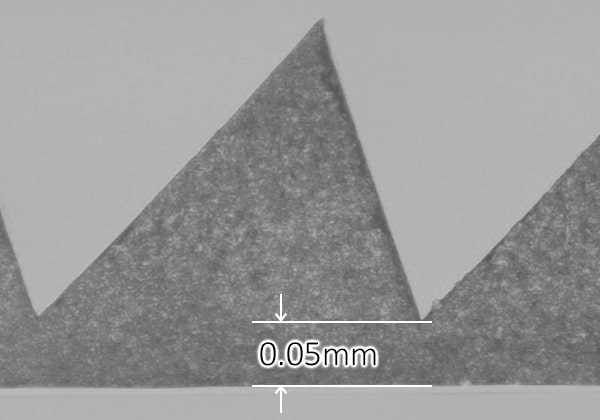

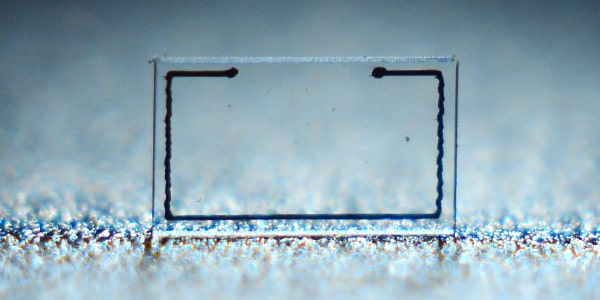

Ultra-thin

molding

Conventional plastic molding is limited to the minimum thickness of 200-300 microns, but depending on the shape, our process can produce ultra-thin lenses measuring only 50 microns or less.

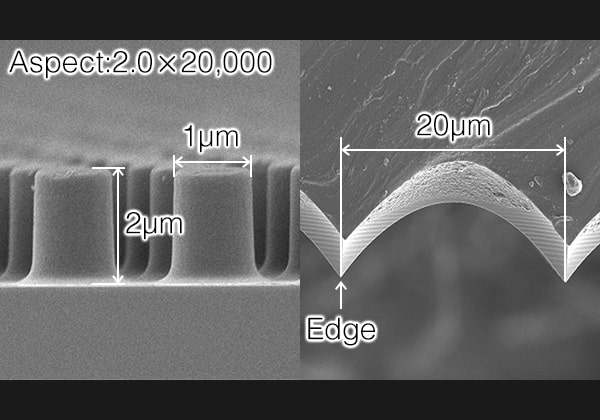

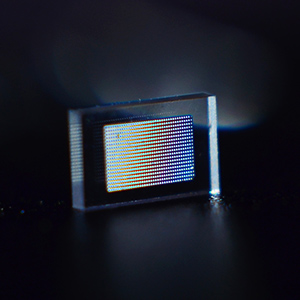

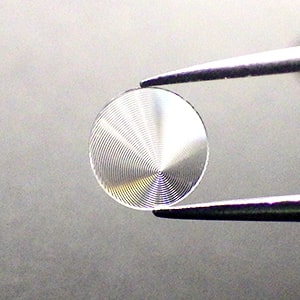

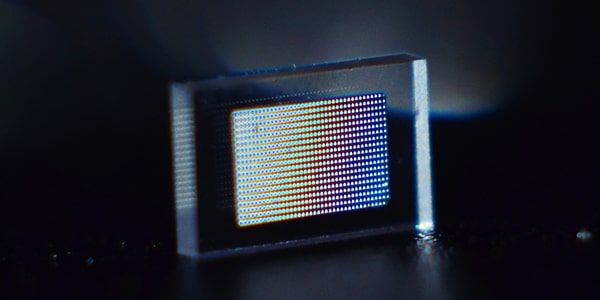

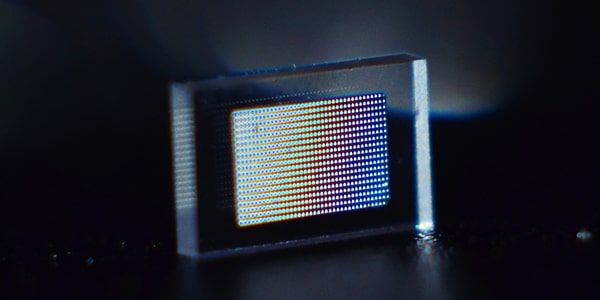

Ultra-fine

molding

The wafer-level lens process can mold a sub-micron size structure and sharp tip so that extremely fine prism manufacture is feasible. Moreover, super-fine patterns in nano order scale can be made.

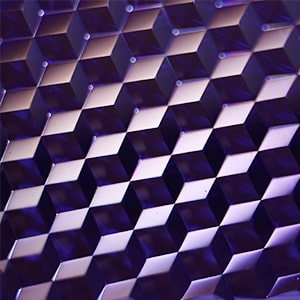

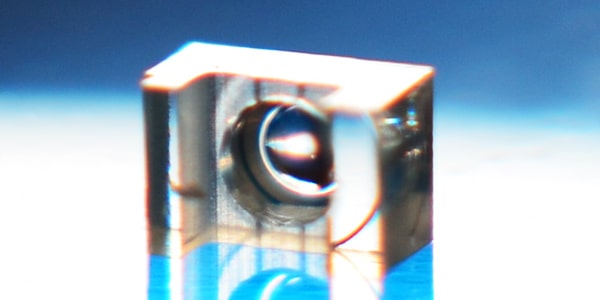

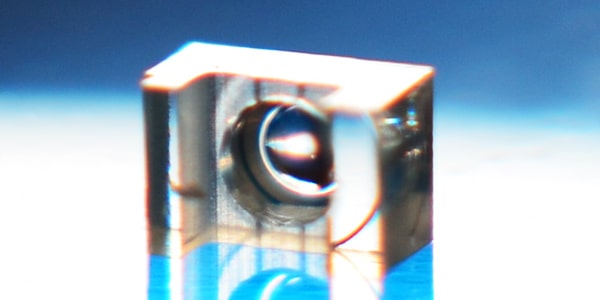

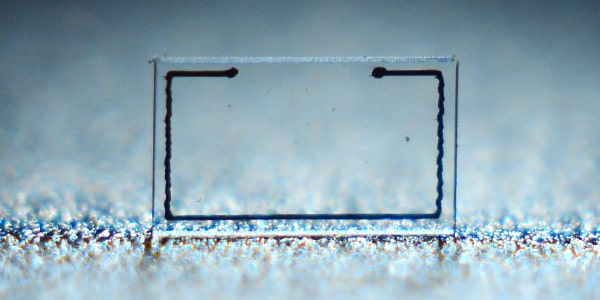

High-aspect-ratio

molding

We can mold lenses of eccentric thicknesses (high aspect ratio) and mechanical structures that are difficult to produce via conventional injection molding.

Products

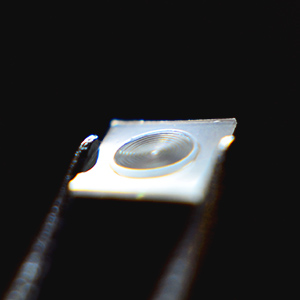

Sensing Optics

(optical components for sensors)

- Overview

-

- Units can be manufactured with a lens designed to accommodate various light sources such as visible light LEDs, infrared LEDs, and VCSEL (laser).

- Lens designs that are difficult to manufacture with injection molding - such as thin, small and complex shapes - can be mass-produced to specific optical requirements.

- Accommodates mass production of up to millions of units/month.

- Applications

-

- Mobile devices (smartphones, wearable devices)

- Smart home devices

- Robots, drones, etc.

- Application Examples

-

- Flash lens

- Biometric authentication

- 3D segmentation

- Diffusion lens used for other light sources

Illumination Optics

- Overview

-

- Units can be manufactured with a lens designed to accommodate various light sources such as visible light LEDs, infrared LEDs, and VCSEL (laser).

- Lens designs that are difficult to manufacture with injection molding - such as thin, small and complex shapes - can be mass-produced to specific optical requirements.

- Accommodates mass production of up to millions of units/month.

- Applications

-

- Mobile devices (smartphones, wearable devices)

- Smart home devices

- Robots, drones, etc.

- Application Examples

-

- Flash lens

- Biometric authentication

- 3D segmentation

- Diffusion lens used for other light sources

Imaging Optics

- Overview

-

- High-aspect lenses can also be manufactured to provide focus-free lenses.

- Accommodates the reflow process.

- Accommodates wafer stacking and optical coating.

- Applications

-

- Home security devices

- Office-use surveillance cameras

- Ultra-small imaging cameras

- Application Examples

-

- Motion sensors

- Collimator lenses

- Biometric authentication

Customized Optics

We can devise the optimal optical materials to meet customer requirements for various applications.

Applications

| Space-saving of device | Power-saving of device | Ensuring designability | Durability | Various additional functions | Customizability | |

|---|---|---|---|---|---|---|

| Solutions | Resistance to high heat processing (260℃) | Focus adjustment-free | Less noticeable | Environmental test endurance | Coating | Customizing to requirements |

| Applications | Smartphones VR |

Home devices | Smartphones Home devices |

Smartphones Automotive lenses |

Smartphones Industrial robots |

Smartphones Robots Automotive electronics Wearable devices |

| Core technologies | Molding technique of high heat-resistant (reflowable) material | High precision wafer stacking, and molding technique | Molding technique with no dependence on shape | Material compounding technique | Technique of layering silver circuit | Molding technique |

| Products |  Imaging lenses, Imaging lenses,Diffusing lenses |

Imaging lenses Imaging lenses |

Diffusing lenses Diffusing lenses |

Imaging lenses, Imaging lenses,Diffusing lenses |

Diffusing lenses Diffusing lenses |

Imaging lenses, Imaging lenses,Diffusing lenses |

| Space-saving of device | |

|---|---|

| Solutions | Resistance to high heat processing (260℃) |

| Applications | Smartphones, VR |

| Core technologies | Molding technique of high heat-resistant (reflowable) material |

| Products |  Imaging lenses, Diffusing lenses Imaging lenses, Diffusing lenses |

| Power-saving of device | |

|---|---|

| Solutions | Focus adjustment-free |

| Applications | Home devices |

| Core technologies | High precision wafer stacking, and molding technique |

| Products |  Imaging lenses Imaging lenses |

| Ensuring designability | |

|---|---|

| Solutions | Less noticeable |

| Applications | Smartphones, Home devices |

| Core technologies | Molding technique with no dependence on shape |

| Products |  Diffusing lenses Diffusing lenses |

| Durability | |

|---|---|

| Solutions | Environmental test endurance |

| Applications | Smartphones, Automotive lenses |

| Core technologies | Material compounding technique |

| Products |  Imaging lenses, Diffusing lenses Imaging lenses, Diffusing lenses |

| Various Additional functions | |

|---|---|

| Solutions | Coating |

| Applications | martphones, Industrial robots |

| Core technologies | Technique of layering silver circuit |

| Products |  Diffusing lenses Diffusing lenses |

| Customizability | |

|---|---|

| Solutions | Customizing to requirements |

| Applications | Smartphones, Robots, Automotive electronics, Wearable devices |

| Core technologies | Molding technique |

| Products |  Imaging lenses, Diffusing lenses Imaging lenses, Diffusing lenses |