Investor RelationsAt a glanceWe support the worldwide monozukuri manufacturing through the power of chemistry.

About Daicel

Celluloid is the world's first industrialized plastics, and in the 1900s, Japan began producing raw materials for celluloid. However, the subsequent increase in demand led to a proliferation of domestic celluloid manufacturers and intense competition, resulting in a decline in quality from the mass production of inferior products and the indiscriminate felling of camphor trees. Eight leading manufacturers concerned about the situation sought to restructure the industry by merging to form Dainippon Celluloid Co., Ltd., the predecessor of today’s Daicel Corporation. Daicel has continued to research and develop products that meet the needs of the times, and been offering a wide range of products, including today's mainstay products, cellulose acetate and Engineering Plastics.

Furthermore, we have been working on the innovation of production technology in chemical plants, including DAICEL Production Innovation. Currently, we have 73 companues in 15 countries and regions around the world as of March 2025, with approximately 10,000 consolidated employees.

Just as the eight celluloid companies joined hands to enrich society, Daicel will work with customers and partners to develop a sustainable society.

Moreover, we will continue to change the future for the better through the power of chemistry by remaining true to our aspirations as a company that make lives better by co-creating value.

Daicel Group’s Three Main Strengths

- Pioneering Research and Development in Biomass Chemistry

- Development of Unique Technologies Since the Company’s Foundation

- Pursuit of Production Efficiency Through DAICEL Production Innovation

Pioneering Research and Development in Biomass Chemistry

Since its establishment in 1919, Daicel has always been involved in biomass chemistry, the production of chemicals from plant-derived raw materials. The celluloid business, which is based on camphor, is our ancestral business, and celluloid acetate, which overcomes celluloid’s flammability, is still one of our core products. Moreover, after the oil crisis of the 1970s, we were among the first to switch to raw materials that did not rely on petroleum in a national project called C1 Chemistry, which aimed to eliminate the dependence on petroleum.

Recently, natural-derived chemistry has been gaining attention as a new valuable environmentally-friendly material due to changes in social needs. Daicel will continue to create products based on renewable resources that contribute to people's daily lives and a sustainable society.

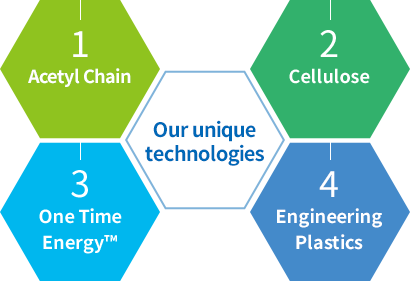

Development of Unique Technologies Since the Company’s Foundation

1. Acetyl ChainTechnology that built the acetyl chain

We are the only acetic acid manufacturer in Japan, and have built a series of characteristic acetyl chains that manufacture acetic acid derivatives such as acetyl chemicals and cellulose acetate from acetic acid. We are developing our business from a strong position globally.

2. CelluloseTechnology for controlling physical properties of cellulose, a natural material

Utilizing the knowledge and technology related to cellulose that we have accumulated over many years since our founding, we are developing high-performance products centered on cellulose acetate, such as acetate fibers, filter materials, liquid crystal panel film materials, and cosmetic materials, in a wide range of fields.

Cellulose Acetate

3. One Time Energy®Expanding technologies accumulated over many years into new fields

Since the commercialization of automobile airbag inflators, we have continued to manufacture gas generators and have contributed to automobile safety. We define the technology cultivated in inflator manufacturing as "One Time Energy®, which generates optimal energy instantly, reliably, and safely," and we are working to apply this technology in a wide range of fields.

One Time Energy®

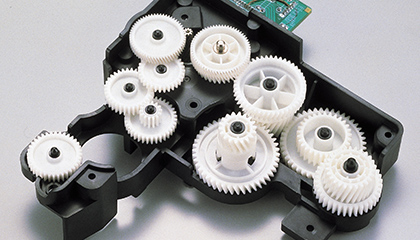

4. Engineering PlasticsBroad product lineup and technological solutions

Our strength lies in our wide-ranging product lineup, from general-purpose resins to super engineering plastics in addition to our engineering plastics, which have a large share of the global market. We also have technical solution centers around the world, and we provide technical solutions to our customers by making full use of the know-how and data we have cultivated.

Engineering Plastics

Pursuit of Production Efficiency Through DAICEL Production Innovation

As a chemical company, DAICEL Production Innovation supports the foundations of manufacturing. We visualized the flow of approximately 8.4 million instances of decision-making related to plant operations that were known by expert operators, and incorporated them into the operation support system. As a result, productivity has almost tripled at our Aboshi plant in Japan.

In 2020, we developed the Autonomous Production System, which represents an evolution of DAICEL Production Innovation. In addition to safety and quality, it also contributes to CO2 emissions reduction by optimizing energy use, and prevents problems by predicting equipment modulation in advance, in pursuit of ultimate production efficiency. We will introduce this system to our group plants in Japan to increase the competitiveness of manufacturing by reducing the workload and using the time saved for more creative work.

Consolidated Net Sales and Operating Income

- FY2025/3Consolidated Net Sales¥586.5 billion

- FY2025/3Consolidated Operating Income¥61.0 billion

Segment Information

Daicel operates in five segments.

*FY2025/3

Medical / Healthcare

In a society that values QOL, we provide safe, high quality healthcare materials and solutions related to pharmaceutical development.

| Main business | Main products and services |

|---|---|

| Life Sciences | Chromatographic columns/stationary phases (chiral columns and achiral columns), chiral reagents, seperation servises/purification services, analytical services, reagents for genetic analysis research, pharmaceutical additives, new drug delivery devices |

| Healthcare | Cosmetic ingredients (polyglycerols, spherical cellulose acetate particles (BELLOCEA®), etc.), functional food ingredients (equol, konjac ceramide, urolithin, and lactobionic acid, etc.) |

*QOL: Stands for Quality of Life and refers to not only physical wealth but also mental quality of life

Smart

Providing the electronic materials market with new solutions that support pleasant lifestyles and technological innovation.

| Main business | Main products and services |

|---|---|

| Functional Products | Alicyclic epoxy, caprolactone derivatives, optical lenses |

| Advanced Technology | Polymers for photoresists, solvents for electronic materials, high-performance films |

Safety

Using One Time Energy®, technology cultivated through our airbag inflator business, for which we boast a strong share of the global market, to provide safety and peace of mind to a wide range of industries.

| Main business | Main products and services |

|---|---|

| Mobility | Automobile airbag inflators |

| Industry | Pyro-Fuse, gas generators for seat belt pretensioners (PGG) |

Materials

Providing value to a wide range of industries on the strength of a diverse line of products centered on acetyl chains and our unique manufacturing methods.

| Main business | Main products and services |

|---|---|

| Acetyl | Acetic acid, acetic, acetate tow |

| Chemical | Cellulose acetate for LCD optical films (TAC), cellulose acetate, 1,3-butylene glycol (1,3-BG), ethyl acetate, ketene derivatives, ethylamine |

Engineering Plastics

Using technical skills cultivated through our work as a pioneer in engineering plastics to provide highly functional and high-value-added solutions to a wide range of industries.

| Main business | Main products and services |

|---|---|

| Polyplastics | Polyacetal (POM), polybutylene terephthalate (PBT), polyphenylene sulfide (PPS), liquid crystal polymer (LCP), and cyclic olefin copolymer (COC) |

| Daicel Miraizu | Water-soluble polymers, barrier films for packaging and AS resin |

Daicel's History and Future

Ever since its founding in 1919, Daicel has a history of progress by meeting the needs of society as it changes over time and developing and providing products that contribute to sustainability.

Looking to the future, in FY2020 we formulated the 4th Long-Term Vision "DAICEL VISION 4.0" centered on our sustainable management policy, and from FY2021 we have launched the Mid-Term Management Strategy “Accelerate 2025”. We continue to work on improving the corporate value of Daicel Group and contributing to building a circular society.

1919-

CelluloidEnrichment of daily life

As a pioneer in the field of plastics, we played an integral role in the development of the Japanese chemical industry.

Cellulose acetateSecuring safety

1938 Commercialized cellulose acetate, offering a solution to flammability concerns associated with cellulose nitrate.

Development of Our Celluloid Business and Creation of a New Organic Chemicals Business

Daicel was founded in 1919 through the merger of eight celluloid companies. From the beginning Daicel worked to make celluloid less inflammable and ended up developing acetate plastic. After establishing the Arai Plant in 1935, we then in 1938, laid the foundations for our cellulose and organic chemicals businesses by setting up a system for consistent production of the raw material cellulose acetate from acetic acid.

the 1950s

Tri-Acetate Cellulose (TAC)Fireproofing films for movies and photography and adding advanced properties

1953 We began producing TAC and after 2000, this business grew significantly as the material came to be used for optical film.

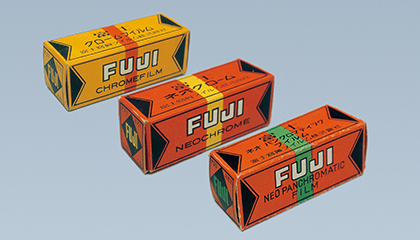

Full-Scale Production in Our Cellulose Business and Starting Our Pyrotechnic Devices Business

Production of acetate plastic went into full operation at our Aboshi Plant in 1950, and in 1953, joint research with Fuji Photo Film Co., Ltd.* led to the beginning of production of TAC, and in 1958 our Sakai Plant began production of acetate toe, which is used in cigarette filters, rounding out our cellulose business. Since cellulose nitrate is a raw material for pyrotechnics, our pyrotechnic business developed, and we established the Harima Plant in 1954.

*Now known as Fujifilm Corporation

the 1960s

Polyacetal (POM)Taking on the challenge of Metal Replacement

1964 Daicel began manufacturing engineering plastics, which serve as metal substitutes in automobiles and other products. Their use has contributed to the development of lightweight components and contributed to a reduction in the environmental load.

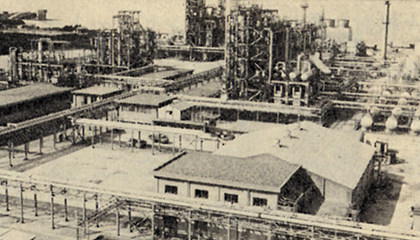

Entry into the Petrochemical Business

During the 1960s, Daicel participated in Japan’s first petrochemical complex and began its petrochemical business with the construction of the Ohtake Plant. In the synthetic resins business, in addition to manufacturing AS resin and ABS resin, Daicel entered into a joint venture with the U.S. company Polyplastics, Co. Ltd.* and went into the engineering plastics business.

*Polyplastics, Co. Ltd. became a wholly owned subsidiary of Daicel in FY2021/3.

the 1980s

Acetic acid using the methanol carbonylation processRealignment of the acetic acid sector

1980 Introduced the methanol carbonylation process to produce acetic acid, our core material, which led to the realignment of the acetic acid sector.

Strengthening the Foundations of Our Acetic Acid Business

In order to deal with a structural slump and to strengthen our main businesses, we went into the methanol carbonylation business, which was the cutting-edge technology at the time, as part of an effort to switch to raw materials that do not depend on petroleum. Participating in the C1 Chemistry Project*, we played a role in reorganizing the acetic acid industry.

*C1 Chemistry was a national project which aimed to break away from over-reliance on oil during the 1970s energy crisis.

Chiral columnsProvision of safe medicine

1982 Started producing chiral columns, which are used to separate substances that may otherwise cause adverse side effects.

Automobile airbag inflatorsProvision of safety and security

1988 Started supplying the key component for automobile airbag systems that protect passengers in the event of a collision.

Proactive Expansion of Our Businesses Overseas

During the 1980s, we established local subsidiaries in Europe, the United States, and Asia. In 1988, we established a subsidiary for manufacturing inflators for automobile air bags. In 1990, we set up a manufacturing base for optical isomer separation in the United States, and in 1992, we began manufacturing acetate toe at a joint venture company in China.

the 2000s

Autonomous Production SystemImprovements in productivity

2000 Daicel Production Innovation Established.

2020 Daicel made use of artificial intelligence to develop the Autonomous Production System, a more evolved version of Daicel Production Innovation.

Expansion of the Inflator and TAC Businesses and Lateral Development of Daicel Production Innovation

We have expanded our inflator business and established bases for that purpose in six countries around the world. We have also expanded our display business by taking TAC, originally a raw material for movie and other films, and using it for manufacturing optical film. In the area of technology, we are opening the Daicel Production Innovation system that we established at the Aboshi Plant and gradually extending it to the entire company and accelerating our process innovations. In 2017, we opened Innovation Park as a center for research and development and concentration of production technology.

2022 and beyond

Mid-Term Management Strategy Launch of “Accelerate 2025”

Uncovering new needs, starting new businesses in order to co-create value with our customers and business partners, and constructing new biomass product trees with environmentally-friendly new technology, we will contribute to construction of a circular society with Daicel's unique efforts and determinations.

Marine biodegradable cellulose acetateSolution for marine plastic

We have noticeably improved marine biodegradability of naturally derived and biodegradable cellulose acetate, and we are continuing to develop other environmentally-friendly products.

Product Deployment with One Time Energy®Pioneering new uses through reinterpretation of the functions of existing technology

We are taking the technologies that we have developed safely, accurately, and instantaneously by generating a single burst of optimal energy and adapting them to uses in industries such as health care and automobiles.