Pin Pusher and Pin Puller, Puncher

Pin Pusher and Pin Puller

The Pin Pusher and Pin Puller enables push/pull out operation, activated by generated gas applying our "One Time Energy".

They could be utilized for various purposes such as an automatic fire extinguisher, safety equipment for emergency, and unlocking stoppers.

Daicel's' "One Time Energy" is fully applied to our Puncher that enables instantaneous push/pull out operation of piston.

Application

-

Automatic fire extinguisher

-

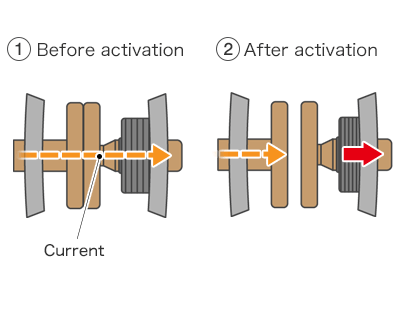

Current breaker due to contact separation

The Pin Puller detaches the contact point, enabling shutdown of electric currents.

-

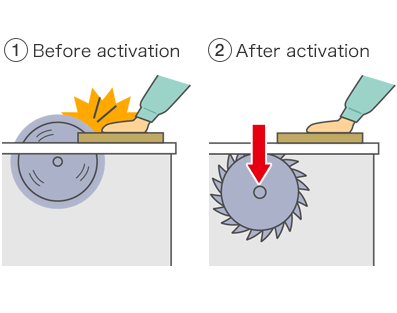

Safety system/emergency stop system for table saw

The Pin Pusher protects the user's hands by pushing down the rotation axis of the electric saw.

*This photo is for illustrative purposes.

active fields

Mobility Disaster prevention Plant, Installation Drone Aerospace

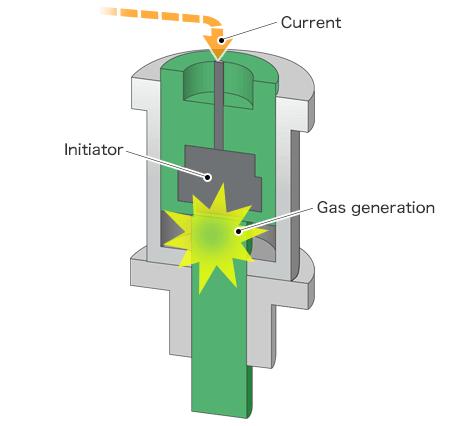

Operating principle of the Pin Pusher, Pin Puller

These devices ensure the safety of users by generating high energy pressure instantenously activated by an electric signal through remote operation.

This devices could be applied for various uses by changing the end shape of the pin.

Pin Pusher

| Function (breaking) time | <50ms |

|---|---|

| Holding force | >245N (2min) |

| Pin stroke | 7.5mm |

| Geometry (D×W×L:mm) |

φ30×48.1 |

| Unit weight | 130g |

| Product Data Sheet (PDF) |

PDF:269KB |

Pin Puller

| Function (breaking) time | <2ms |

|---|---|

| Holding force | >550N |

| Pin stroke | 5.0mm |

| Geometry (D×W×L:mm) |

φ16.2×37.2 |

| Unit weight | 14g |

| Product Data Sheet (PDF) |

PDF:245KB |

Operating principle

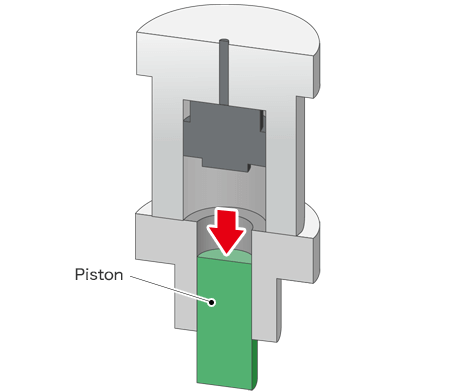

Operating principle of the Pin Pusher

-

1.An ignition current is generated from an external signal. "One Time Energy" activates to generate gas.

-

2.The piston is pushed out.

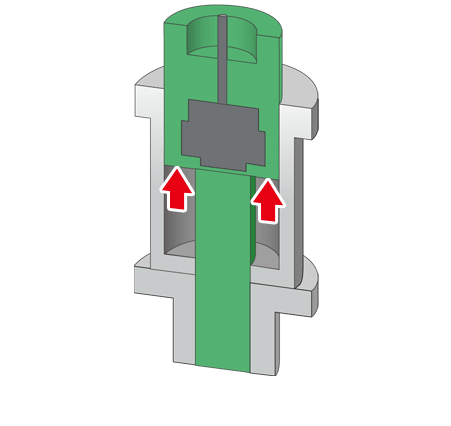

Operating principle of the Pin Puller

-

1.An ignition current is generated from an external signal. "One Time Energy" activates to generate gas.

-

2.The piston is pulled in.

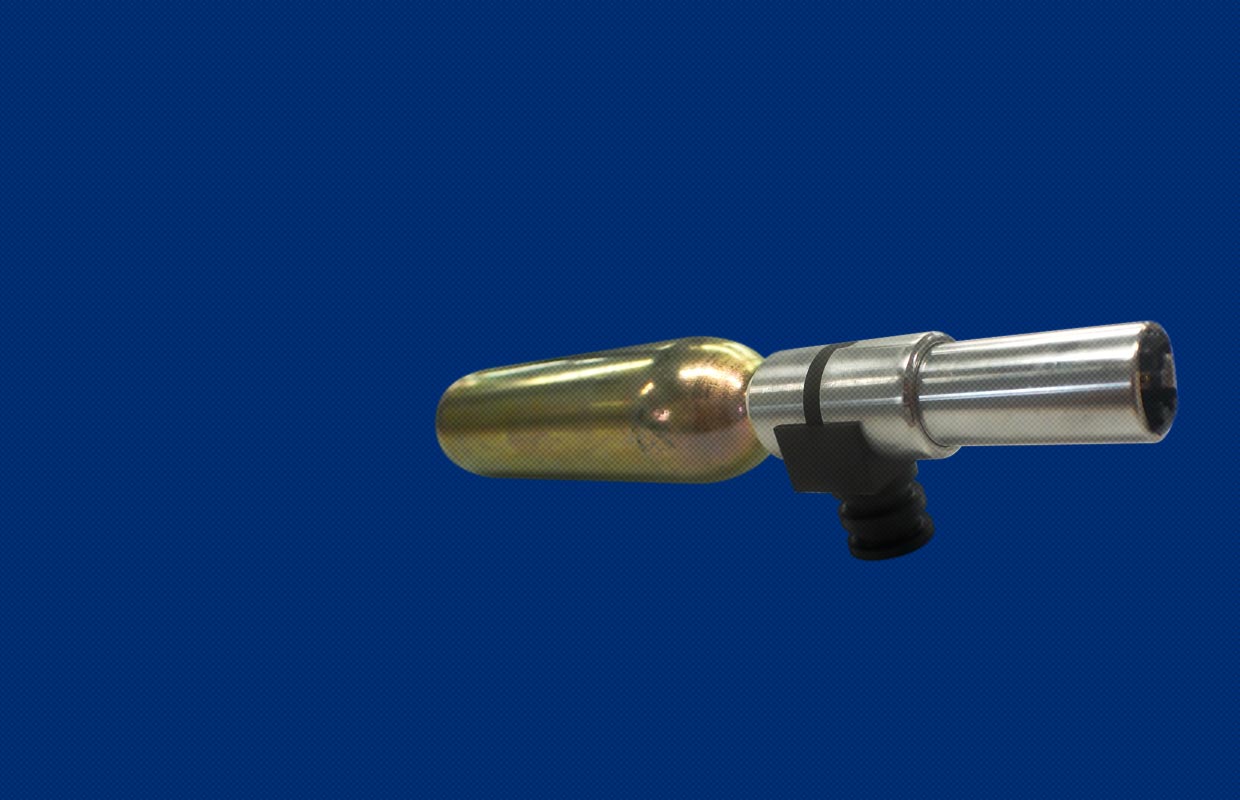

Puncher

Puncher enables gas generation activated by an electrical signal, releasing gas from various gas cartridges.

We provide broad applications of Puncher requirements

that could be used for various purposes such as inflating airbag, operating automatic fire extinguisher etc.

Daicel Safety Strategic Business Unit(SBU)s' "One Time Energy" is fully applied to our Puncher that enables safe,

instantaneous release of compressed gas from the gas cartridge.

Application

-

Protective jacket for motorcycle riding

-

Airbag for mitigating drone fall impact

-

Energency Shut-off valve

Gas pressure generated by One Time Energy closes the valve.

-

Automatic fire extinguisher

*This photo is for illustrative purposes.

active fields

Mobility Lifesaving Disaster prevention Plant, Installation Drone

Features / Specifications

Our Puncher is activated by an electrical signal, instantaneously generating and releasing compressed gas.

It also can be installed on small gas cartridges (5/8-18UNF*).

*Please feel free to contact us if you wish for more information on gas cartridges with a different screw diameter.

| Release start time | <5ms |

|---|---|

| Screw size | 5/8-18UNF *Please feel free to contact us if you wish for more information on gas cartridges with a different screw diameter. |

| Specification of gas outlet | φ15.9 *Please feel free to contact us if you wish for more information about a different gas outlet. |

| Geometry (D×W×L:mm) |

66.7×37×22 |

| Unit weight | 38g |

| Product Data Sheet (PDF) |

PDF:337KB |

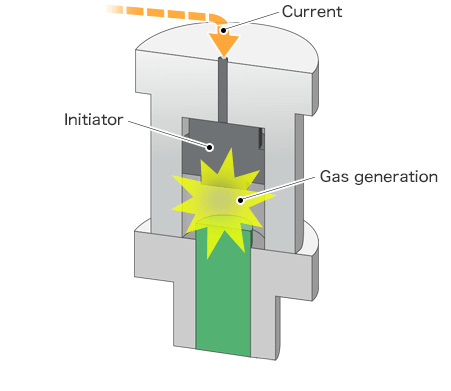

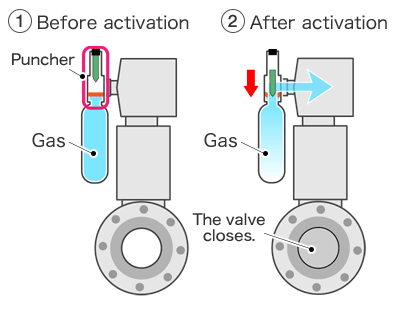

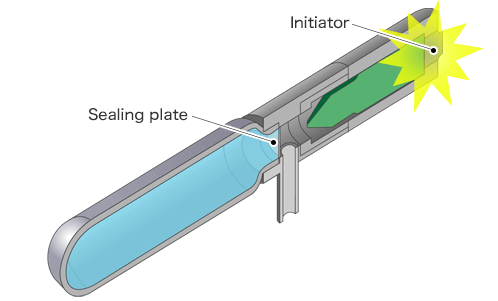

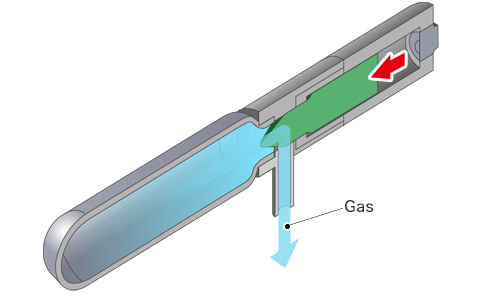

Operating principle of the Puncher

-

1.An ignition current is generated, activated by an external signal. One Time Energy operates to generate gas.

-

2.The piston pushed by the generated gas punches the sealing plate, releasing compressed gas.