Introduction of research

Putting a chemical plant in a glass plate.

Ultra-efficient microreactions

significantly transform conventional thinking about plants.

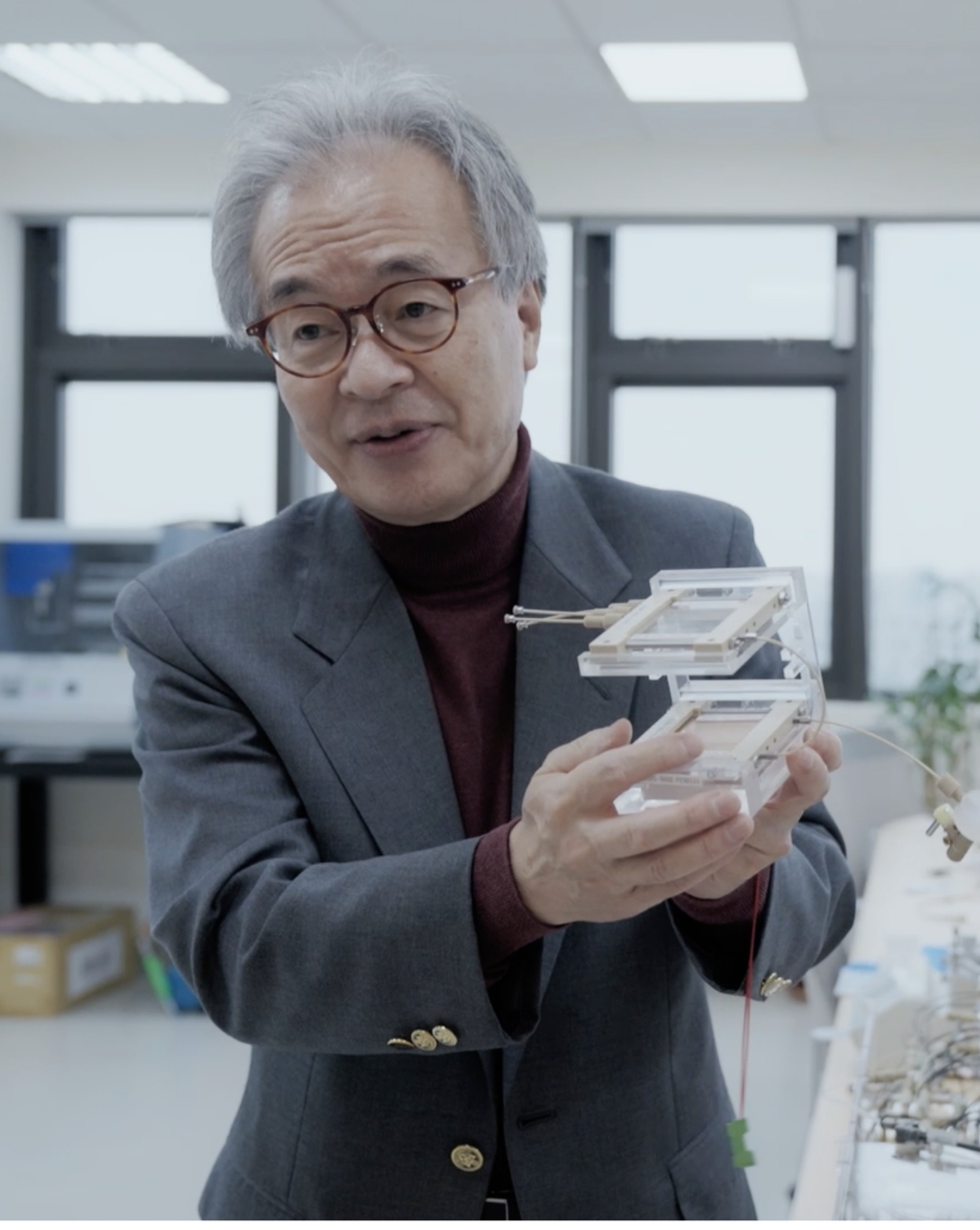

Originator of the microfluidic device

Takehiko Kitamori, Ph.D.

In our device, various kinds of fluids are introduced into microchannels, which are thinner than hair and etched into a 7 × 3 cm glass plate, to perform chemical reactions and chemical operations. Our idea was this: fit a large chemical plant into this small glass device.

Vol1.

A Micro Plant revolution

that transforms conventional thinking about chemical plants

7 min 22 sec (This video is in Japanese.)

- Putting a chemical plant in a glass plate

- Why is microfluidics effective?

- Ultimate ultra-efficient, waste-free production

- Novel concept plants created by increasing the number of devices

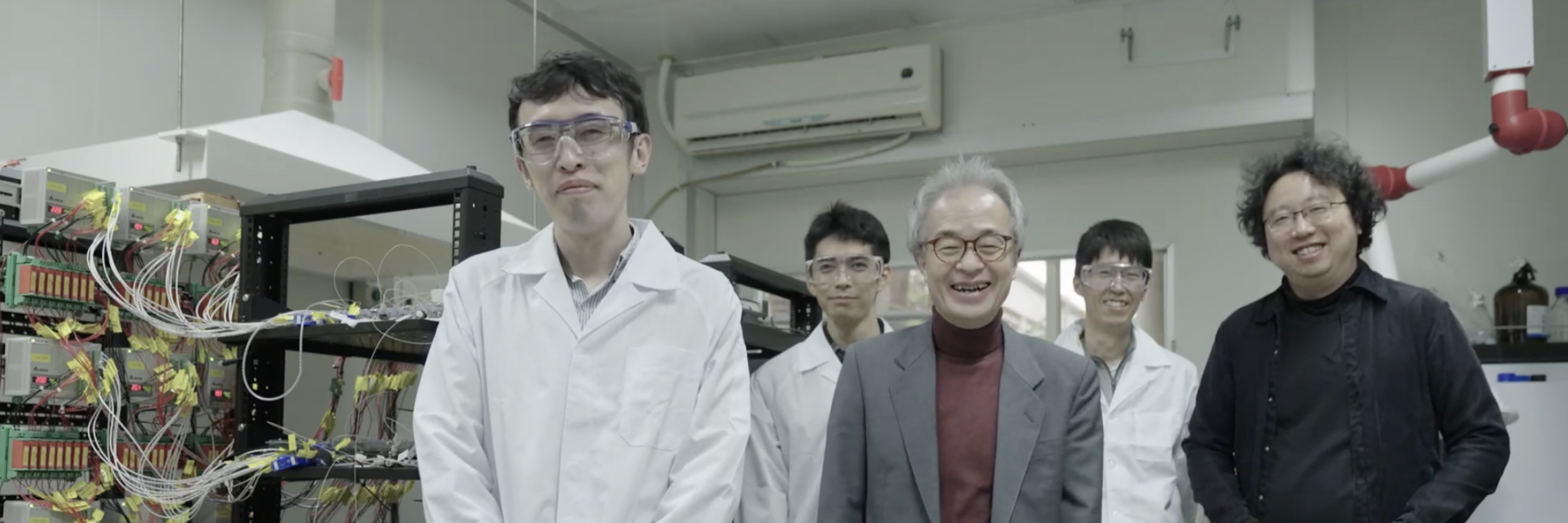

Fusion of the flexibility and diversity of Taiwan with the creative technology of Japan promotes ultimate carbon neutral technology.

IMT Taiwan x National Tsing Hua University (Taiwan) x Daicel

A breakthrough was made in the social implementation of unique technologies created by Japanese combined with the flexible environment of Taiwan and Daicel's strong driving force.

By sharing our unparalleled achievements, we will spread this technology around the world to realize a carbon-neutral society.

Vol. 2

Evolving creative carbon neutral technology

that originated in Japan through global co-creation

Part 1

5 min 8 sec (This video is in Japanese.)

- IMT Taiwan

- Reducing a 20 m plant to 2 m — toward ultimate carbon neutrality

- Its compact size enables the installation of production equipment in the right place — on-site production

Vol. 3

Evolving creative carbon neutral technology

that originated in Japan through global co-creation

Part 2

8 min 24 sec (This video is in Japanese.)

- Various innovations and new industries arising from social implementation of the Micro Plant *

- New plant planning / flexibility & diversity

- Micro-unit operations with components for unit operations connected like electrical circuits

*IMT Taiwan:

IMT Taiwan was established in 2021 as a spin-off company of National Tsing Hua University. It aims to expand the realm of microchemical technology from laboratory- to industrial-scale chemical synthesis and environmental analysis and to bring about innovation in this field. Currently, it is mainly focused on the development of a desktop chemical plant that realizes miniaturization while maintaining the same production capacity as a conventional chemical plant, but it plans to expand its business extensively to the biotechnology and medical fields in the future.

URL:

https://imtt.com.tw/en/

*Institute of Microchemical Technology Co., Ltd. (IMT):

IMT is a pioneering company in the manufacture of microchemical chips that was established in 2001 as a venture company by the University of Tokyo and Kanagawa Academy of Science and Technology (present Kanagawa Institute of Industrial Science and Technology). At present, in addition to microchemical chips, it also manufactures and sells peripheral devices, such as laboratory accessories, liquid supply devices, and system equipment.

URL:

https://www.i-mt.co.jp/en/