The characteristics of diamonds remain the same even at nanoscale.

A thermal stabilizer shows stable antioxidant and heat-resistance functions as well as strength retention even at temperatures exceeding 300°C.

Scroll

Thermal stabilizer

An antioxidant function that is stably expressed even in ultra-high temperature ranges

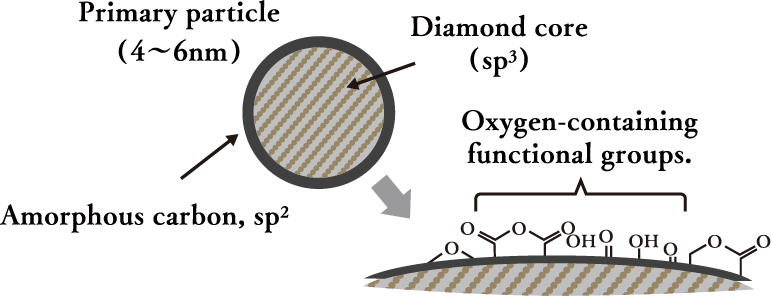

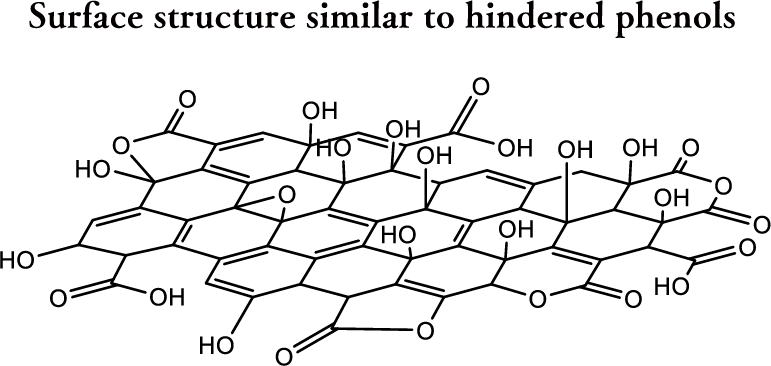

Nanodiamonds can be applied as antioxidizing agents that function even at high temperatures ranging from 260 to 400°C. The outermost surfaces of nanodiamonds contain many sp2 carbon and oxygen functional groups. This surface structure is similar to that of hindered phenol-based resin additives, which are widely used as antioxidizing agents in general, and oxygen function groups on the nanodiamond surface are considered to have a radical-scavenging function (oxidation prevention function).

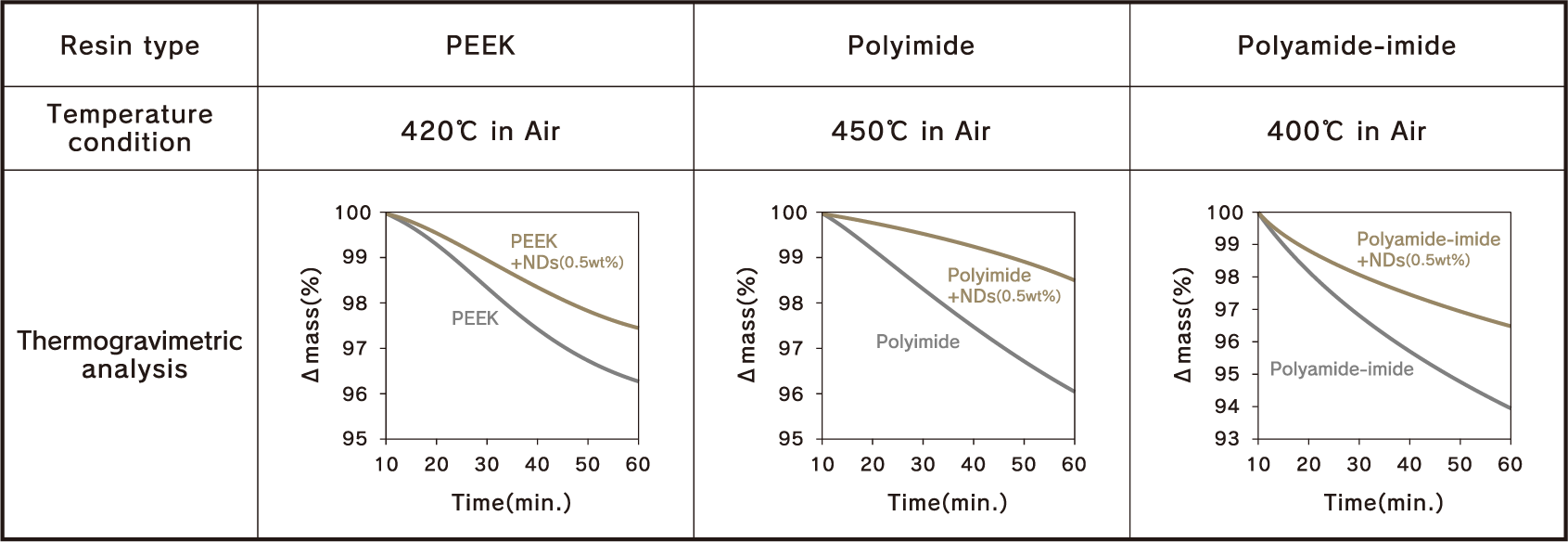

Oxygen function groups in the nanodiamond core (diamond structure at the center) and on the nanodiamond surface have extremely high heat resistance, and it has been confirmed that they exist stably even in high-temperature environments exceeding 300°C. Thanks to this high thermal stability, nanodiamonds are expected to function as antioxidizing agents even for engineering plastics and super engineering plastics (such as PEEK, polyimide, and polyamidimide), which existing antioxidizing agents are incapable of doing.

Reinforcement of the performance of high heat-resistance thin-film coatings

In applications for functioning with a thin layer film coating with super engineering plastics like polyimide and polyamidimide, the heat resistance performance tends to drop compared with the bulk properties. Nanodiamonds can be used as a material to provide reinforcement against such a decrease in heat-resistance performance.

Strength retention in high temperature environments

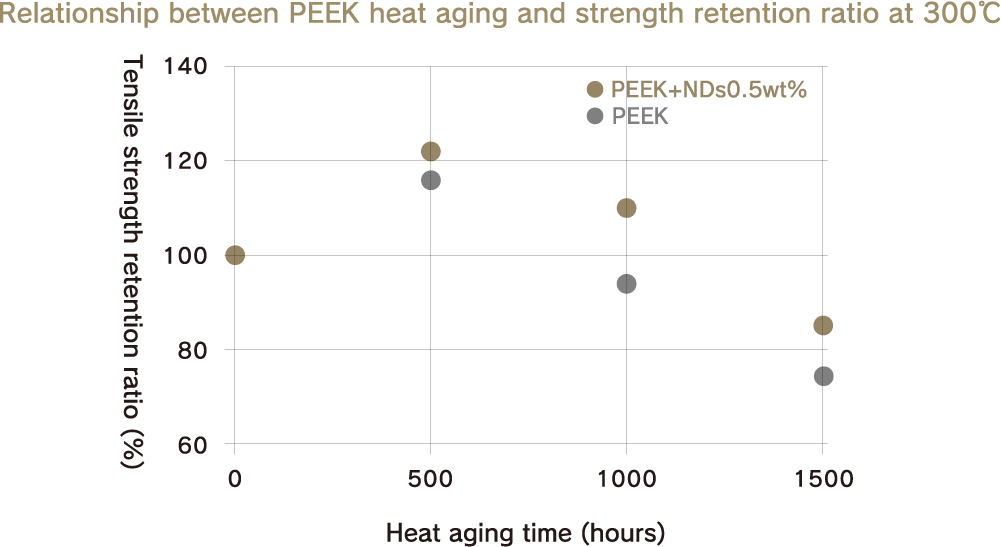

In the case of resin products intended to be used in high-temperature environments, thermal degradation due to high temperatures can be suppressed by the addition of nanodiamonds. This is expected to suppress degradation caused not only by the temperature in the operating environment but also that caused by frictional heat generated by sliding parts, heat transmitted from other parts in contact, and other sources. With PEEK, the effect of improving the tensile strength retention rate is confirmed, as shown in the following graph.